FCX2000 Series

FCX2000 Series Specification

- Product Type

- Flatbed Cutting ploter

- Weight (kg)

- 167.5 lb

- Computerized

- Yes

- Automatic

- Yes

- Control System

- Other

- Cutting Speed

- 400 mm/sec mm/s

- Cutting Thickness

- 1 mm depending upon cutting media & cutting Blade Used. Millimeter (mm)

- Cutting Function

- Full Automatic

- BladeSize

- 0.9 to 1.5 MM

- Voltage

- 100 to 240 VAC, 50/60 Hz (Auto switching) Volt (v)

- Dimension (L*W*H)

- 1344 x 1409 x 930 mm Millimeter (mm)

- Feature

- Low Noise, Environmental Friendly, Good Quality, High Efficiency, Low Energy Consumption

- Warranty

- 1 year

FCX2000 Series Trade Information

- Minimum Order Quantity

- 1 Piece

- FOB Port

- Mumbai

- Payment Terms

- Cheque

- Supply Ability

- 1 Piece Per Week

- Delivery Time

- 4 Week

- Packaging Details

- Wooden Boxes

- Main Domestic Market

- All India

- Certifications

- UL60950-1/cUL, CE marking (Low voltage and EMC) FCC-A, EN55032-A

About FCX2000 Series

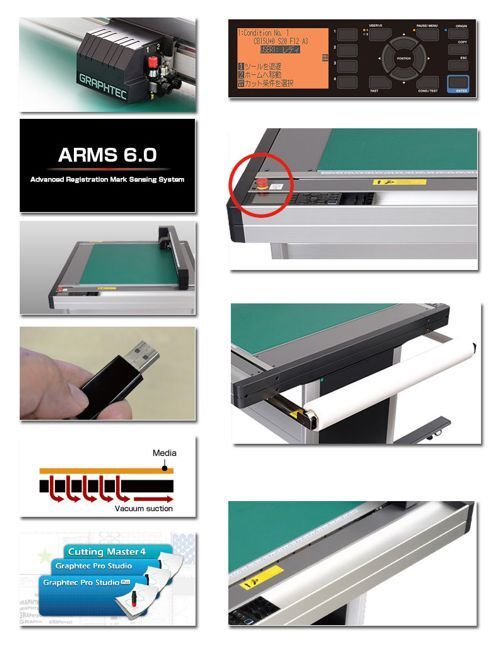

the FCX2000 Series provides the perfect solution for package prototyping and short production runs of rigid materials, eliminating the need for a cutting die. The included dedicated software enables contour cutting, reducing media waste and processing time. This makes the FCX2000 Series the ultimate choice for those looking for a seamless and efficient package prototyping and short production run solution.

Users are empowered to create custom orders at low cost with short delivery times. Redesigned Y bar and cutting table deliver high precision cutting and creasing. New dedicated design software and plug-ins provide all of the tools necessary to create elegant, professional products.

Dual head design delivers 500G and 1000G of force at speeds up to 400mm/s.

Process materials thick or thin including: Rubylith, Static Cling Film, Vinyl, Rubber Sandblast, Diamond Grade Reflective, Chipboard, E-flute and more.

Three table sizes of 24 x 36ï, 48 x 36ï and 70 x 36ï are available utilizing enhanced vacuum suction media hold down.

With Offline USB Operation, individuals with minimal experience can operate the machine directly without requiring a computer. USB operation allows operators of all skill levels to handle various types of media for cutting. Once the designer has created the plot file, it can be shared with users of any experience level to produce. All that is needed is to insert the USB and select the file from the user-friendly 3.7 inch Graphic LCD screen. The cutting conditions are automatically applied, and the job is executed. Additionally, barcodes can be generated for print and cut applications. The cutting data is automatically selected from the USB flash memory by scanning the barcode printed on the media, allowing for seamless contour cutting and reducing the possibility of operator errors.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Flat Bed Cutting Plotter Category

Heavy Duty Flatbed Cutting Plotters

Minimum Order Quantity : 1 Piece

Voltage : 220V/50Hz

Cutting Function : Other, Precision cutting, contour cutting, compensation cutting

Cutting Thickness : Up to 25mm (material dependent)

Product Type : Industrial Flatbed Cutter

Type : Other, Flatbed Cutting Plotter

FC4500 Cutting Plotter

Minimum Order Quantity : 1 Perch

Voltage : AC 100240V, 50/60Hz

Cutting Function : Other, Contour cutting, segment area registration mark reading, perforation, plotting

Cutting Thickness : Maximum 1.0 mm (depends on material)

Product Type : Desktop Cutting and Plotting Machine

Type : Other, Flatbed Cutting Plotter

Send Inquiry

Send Inquiry